Anatomy of a Rocket: Lessons from Starship and Mechazilla

Understanding the critical components that make SpaceX's advancements possible

In the wake of SpaceX's recent successes with the Starship flight test and the groundbreaking capabilities of Mechazilla, we find ourselves at the forefront of a new era in space exploration. These advancements not only push the boundaries of what is possible in aerospace technology but also offer valuable lessons in engineering. In this newsletter, we’ll delve into the intricate anatomy of rockets, using SpaceX's latest successes as a backdrop to explore the science and engineering that make these achievements possible.

The Anatomy of a Rocket

Rockets are sophisticated machines designed for one purpose: to reach space. At a high level, a rocket can be broken down into several key components, each critical to its performance:

1. Propulsion System

At the core of any rocket is its propulsion system, designed to produce the thrust necessary to overcome Earth's gravitational pull. In the case of Starship, SpaceX uses Raptor engines, which are full-flow staged combustion engines powered by methane and liquid oxygen (LOX), producing around 230 metric tons of thrust each. The Raptor engine's ability to be refueled with methane (which can potentially be produced on Mars) makes it an ideal candidate for future interplanetary missions. There are two primary types of propulsion systems: liquid and solid propellants.

Liquid Propellants: These systems use a combination of liquid fuel and oxidizer that are stored in separate tanks and pumped into the combustion chamber. For instance, SpaceX's Raptor engines utilize a regenerative cooling system where the fuel (liquid methane) is circulated around the combustion chamber to absorb heat, preventing overheating and enhancing efficiency. This method also allows for throttling and restarting the engine mid-flight, providing remarkable control.

Solid Propellants: These consist of a pre-mixed solid fuel and oxidizer. While simpler in design and often more reliable for certain applications, solid rockets lack the ability to be turned off and on during flight, limiting their flexibility. The Space Shuttle Solid Rocket Boosters (SRBs) exemplify this type, providing the initial thrust needed during launch.

2. Structure

The structure of a rocket is the skeleton that holds everything together. It must be lightweight, yet strong enough to withstand immense forces during launch and flight. Rocket structures must also manage thermal expansion, vibration, and pressure.

Key Components:

Airframe: The outer shell, usually made from aluminum alloys or stainless steel, provides the external protection and support. Starship, for instance, uses stainless steel, chosen for its high tensile strength, resistance to heat, and ability to withstand the high pressures encountered during flight and re-entry.

Load-Bearing Components: The structure must support the weight of the fuel, payload, and engines, all while enduring extreme forces during launch (like thrust and aerodynamic pressure). Starship’s design incorporates a cylinder-cone shape, optimizing aerodynamics while distributing loads efficiently.

Reinforcement: Reinforcements like stringers (long beams running along the rocket's length) help distribute the loads. They work with ribbed structures to maintain the integrity of the airframe and ensure it doesn’t bend under stress.

Heat Shields: The structure is also responsible for housing heat protection systems, which are critical for the rocket’s survival during re-entry. Starship uses thermal tiles made from ceramic-coated stainless steel, which can withstand the intense heat of atmospheric re-entry without cracking or becoming brittle.

Weight vs Strength:

In rocket engineering, there’s always a balance between weight and strength. While carbon fiber composites are lightweight and strong, they are more fragile under high temperatures compared to stainless steel. This makes stainless steel the better option for rockets that experience extreme heat and pressure, like Starship.

Load Distribution and Stability:

The structure ensures that the weight of the rocket is evenly distributed. This prevents bending or warping during launch, where forces acting on the rocket can be thousands of pounds per square inch. Starship's design emphasizes symmetry, allowing the rocket to remain stable and upright during flight.

3. Fuel Tanks

Fuel tanks are essential for holding the rocket’s propellant. Starship’s propellant tanks are made from the same stainless steel used in the fuselage, providing high pressure tolerance and minimizing weight. These tanks store both methane and liquid oxygen in cryogenic conditions, ensuring optimal fuel performance.

Cryogenic storage is crucial to the high-efficiency combustion in the Raptor engines. These tanks must be insulated to prevent boil-off, a process where the liquid fuel turns into gas due to heat exposure. The design of the Starship’s tanks minimizes this issue through innovative insulation and tank pressure control systems.

3. Avionics and Control Systems

Avionics systems manage the rocket's flight path and ensure stability during launch and landing. Starship is equipped with advanced computers and sensors that continuously monitor a range of critical parameters, such as altitude, speed, orientation, and even external forces acting on the rocket. By processing this data, avionics can make real-time adjustments to maintain the rocket’s trajectory.

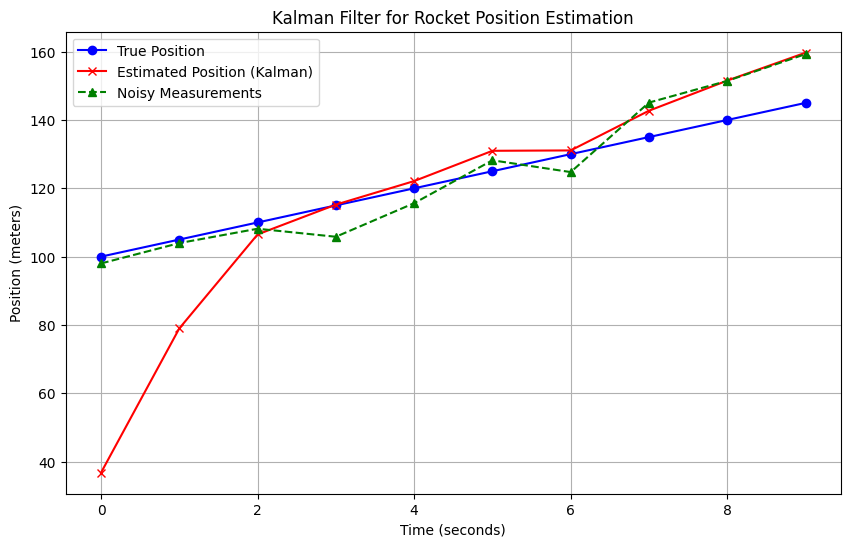

A key component in modern avionics systems is the Guidance, Navigation, and Control (GNC) system. This system uses sensor data and advanced algorithms to keep the rocket on its intended flight path. For instance, one of the most vital algorithms in GNC systems is the Kalman filter. This mathematical algorithm fuses predictions from the rocket’s motion model with noisy sensor data, allowing for more accurate estimation of variables like position, velocity, and attitude. By continually refining these estimates, the Kalman filter helps ensure that real-time adjustments are precise, enabling the rocket to navigate complex maneuvers safely, from launch to reentry.

For rockets, Inertial Measurement Units (IMUs) provide raw data, such as acceleration and rotation rates. The Kalman filter processes this information to minimize error and predict the rocket's current state (position, velocity, etc.). Let’s explore how a simplified version of this works in code.

Below is an example code in Python that demonstrates how a Kalman filter might be applied to estimate a rocket's altitude and velocity based on sensor data from an IMU:

import numpy as np

import matplotlib.pyplot as plt

# Time step (e.g., every second)

dt = 1.0

# State vector: [position, velocity]

x = np.array([[0], # initial position

[0]]) # initial velocity

# State transition matrix A

A = np.array([[1, dt],

[0, 1]])

# Control matrix B (assumed zero here, but could include thrust inputs)

B = np.array([[0.5 * dt**2],

[dt]])

# Process noise covariance Q (uncertainty in model)

Q = np.array([[1, 0],

[0, 1]])

# Measurement matrix H (what sensors measure)

H = np.array([[1, 0]])

# Measurement noise covariance R (sensor noise)

R = np.array([[5]])

# Initial estimate covariance P

P = np.array([[1, 0],

[0, 1]])

# Kalman gain placeholder

K = np.zeros((2, 1))

# Function to simulate noisy sensor data (e.g., from IMU)

def get_sensor_data(true_position, noise_variance):

return true_position + np.random.normal(0, noise_variance)

# Simulated true trajectory (straight-line motion)

true_position = 100.0 # meters

true_velocity = 5.0 # meters per second

# Lists to store data for plotting

true_positions = []

estimated_positions = []

measurements = []

# Run Kalman filter for a few time steps

for _ in range(10):

# Simulate IMU position measurement with noise

measurement = get_sensor_data(true_position, 10)

# Predict the next state

x_pred = np.dot(A, x)

P_pred = np.dot(A, np.dot(P, A.T)) + Q

# Kalman gain

K = np.dot(P_pred, H.T) / (np.dot(H, np.dot(P_pred, H.T)) + R)

# Update the estimate with sensor measurement

z = np.array([[measurement]]) # measurement

y = z - np.dot(H, x_pred) # measurement residual

x = x_pred + np.dot(K, y)

# Update the error covariance matrix

P = P_pred - np.dot(K, np.dot(H, P_pred))

# Collect data for plotting

true_positions.append(true_position)

estimated_positions.append(x[0, 0])

measurements.append(measurement)

# Update true position for the next step

true_position += true_velocity * dt

# Plotting results

plt.figure(figsize=(10, 6))

# Plot true positions

plt.plot(true_positions, label='True Position', color='blue', marker='o')

# Plot estimated positions from Kalman filter

plt.plot(estimated_positions, label='Estimated Position (Kalman)', color='red', marker='x')

# Plot noisy measurements

plt.plot(measurements, label='Noisy Measurements', color='green', marker='^', linestyle='--')

# Add titles and labels

plt.title('Kalman Filter for Rocket Position Estimation')

plt.xlabel('Time (seconds)')

plt.ylabel('Position (meters)')

plt.legend()

plt.grid(True)

plt.show()Explanation:

State Vector (

x): Tracks the rocket’s position and velocity.Transition Matrix (

A): Describes how the position and velocity evolve over time.Measurement Matrix (

H): Describes what the IMU is measuring (in this case, position).Process Noise (

Q) and Measurement Noise (R): These capture uncertainties in the model and sensor data.Kalman Gain (

K): A critical part of the filter that adjusts how much we trust the sensor versus the prediction.True Position: The actual position of the rocket over time (blue line).

Estimated Position (Kalman): The position estimated by the Kalman filter (red line). This should converge to the true position, despite noisy measurements.

Noisy Measurements: The raw IMU sensor measurements (green line). These are the actual data the Kalman filter tries to correct and use to improve the state estimate.

In the real-world application, the GNC system integrates data from multiple sources like the IMU, GPS, and even star trackers for precise positioning, allowing Starship to adjust its course during flight.

4. Materials: Light, Strong, Heat-Resistant

The materials used in rocket construction play a crucial role in ensuring the rocket’s performance, especially in terms of strength-to-weight ratio, thermal resistance, and durability. The right materials are essential for withstanding the extreme conditions of launch, space travel, and re-entry.

Key Materials:

Aluminum-Lithium Alloys: These are popular in rocket construction due to their high strength-to-weight ratio. Aluminum-lithium alloys are lighter than pure aluminum, which is important for reducing overall mass. They also exhibit good resistance to fatigue and can withstand cryogenic temperatures, making them ideal for fuel tanks and structural components.

Stainless Steel: Starship uses stainless steel, specifically an alloy called Inconel, which is known for its strength and heat resistance. Stainless steel is capable of enduring the extreme heat and pressure encountered during re-entry without degrading or losing integrity. It also offers corrosion resistance, making it a solid choice for reusable rockets like Starship.

Carbon Fiber Composites: While not used in Starship, carbon fiber composites are commonly used in other rockets due to their lightweight nature and high strength. These materials are particularly useful for non-load-bearing parts, such as the rocket's outer shell or fairings, where reducing weight is critical. However, carbon fiber is less heat-resistant compared to metals like steel.

During re-entry, rockets must withstand extreme temperatures as they pass through Earth’s atmosphere. Starship’s TPS (Thermal Protection Systems) uses a combination of ceramic tiles and the inherent properties of stainless steel. The ceramic tiles protect the structure from intense heat, while the stainless steel’s reflective properties help dissipate thermal energy, preventing the rocket from burning up.

Reinforced Carbon-Carbon (RCC), used on the Space Shuttle, is another example of a material designed to withstand high temperatures. RCC was specifically used for areas exposed to the most intense heat during re-entry, such as the Shuttle's leading edges.

5. Payload: What’s the Rocket Actually Carrying?

The payload is the cargo that the rocket delivers to its destination, whether that be satellites, scientific instruments, or astronauts. It is housed in the payload fairing, which protects it during launch.

For Starship, the payload section is one of the most versatile components. Starship's design allows for the payload bay to be adjusted for various types of missions:

Satellite Launches: Starship can carry multiple payloads for deployment into low Earth orbit (LEO), geostationary orbit (GEO), or even interplanetary missions. This flexibility is due to the large internal volume that can accommodate different satellite sizes and configurations.

Crewed Missions: Starship is also designed to carry astronauts to destinations like the Moon and Mars. The crewed module is designed to include life support systems, advanced radiation shielding, and even artificial gravity during long-duration missions.

Space Cargo: The design can also be used to transport large quantities of cargo to space stations, the Moon, or other celestial bodies. The modularity of the payload section means that it can be optimized for the size and shape of the cargo.

6. Launch Tower and Recovery Systems

The launch tower is a critical component in the rocket’s lifecycle, providing essential support and services before liftoff. It includes fueling systems, electrical connections, and crew access facilities. However, recent innovations have transformed the launch tower into a key part of the recovery process, particularly in SpaceX's approach to rocket reusability.

Mechazilla is SpaceX's next-generation launch tower designed to catch the rocket boosters as they return to Earth after a launch. This system not only increases reusability but also drastically reduces turnaround time for rockets. The system incorporates a set of robotic arms and a grid of catching claws, which work together to snatch the rocket mid-air as it descends.

How Mechazilla Works:

Robotic Arms:

The primary mechanism of Mechazilla involves two massive robotic arms that are positioned to catch the returning rocket's first stage. These arms are designed with a precision catching system to precisely grab and hold the descending rocket.Grid Fins and Catching Claws:

The rocket's descent is controlled using grid fins, which help stabilize its fall as it re-enters the atmosphere. Once the rocket reaches the desired altitude, the Mechazilla claws extend, moving to catch the rocket in mid-air and gently slow it down for landing.Landing on a Platform:

Mechazilla doesn't just grab the rocket from the sky; it also guides the rocket towards a landing platform for easy recovery. This allows SpaceX to reuse the Falcon 9's first stage multiple times, cutting costs and making frequent launches more feasible.Reusability and Turnaround Time:

The main advantage of Mechazilla's design is that it supports rapid recovery and reuse of rockets. Unlike conventional landing methods, where rockets must land and then be transported back to a landing site, the robotic arms dramatically speed up the process by catching the rocket directly from the air. This significantly reduces both the logistical effort and time required between missions, increasing SpaceX’s launch cadence.

SpaceX's vision of fully reusable rockets has been one of the company's most significant advancements in space exploration. The creation of Mechazilla fits into that vision by ensuring rockets can be recovered more efficiently and be reused more often. This increases SpaceX’s ability to reduce the cost of access to space, opening up more opportunities for launches, including space tourism, satellite deployment, and interplanetary exploration.

Comparison with Traditional Recovery Systems:

Traditional Landings: Prior to innovations like Mechazilla, rocket boosters would land on a drone ship in the ocean, requiring recovery and refurbishment. This method took longer and involved higher logistical costs, with the booster often needing to be transported back to port.

Mechazilla: The robotic arm system provides a more direct and faster solution. The arms are capable of catching the booster mid-flight, essentially eliminating the need for transport. This reduces the overall turnaround time significantly.

Conclusion

The recent triumphs of SpaceX's Starship and Mechazilla remind us that the pursuit of space travel is a thrilling amalgamation of science and engineering, driven by relentless innovation. As we dissect the anatomy of rockets, it becomes evident that every component, from the propulsion systems to the coding that guides their flight, is a testament to human ingenuity.

By understanding the intricate details of rocket engineering, we not only appreciate the technology behind space exploration but also the immense challenges that engineers tackle to make the impossible possible. The next time you look up at the stars, remember the precision, creativity, and coding that made that journey achievable.

Great insights in this newsletter! Keep up the fantastic work, your dedication to sharing knowledge truly inspires me!